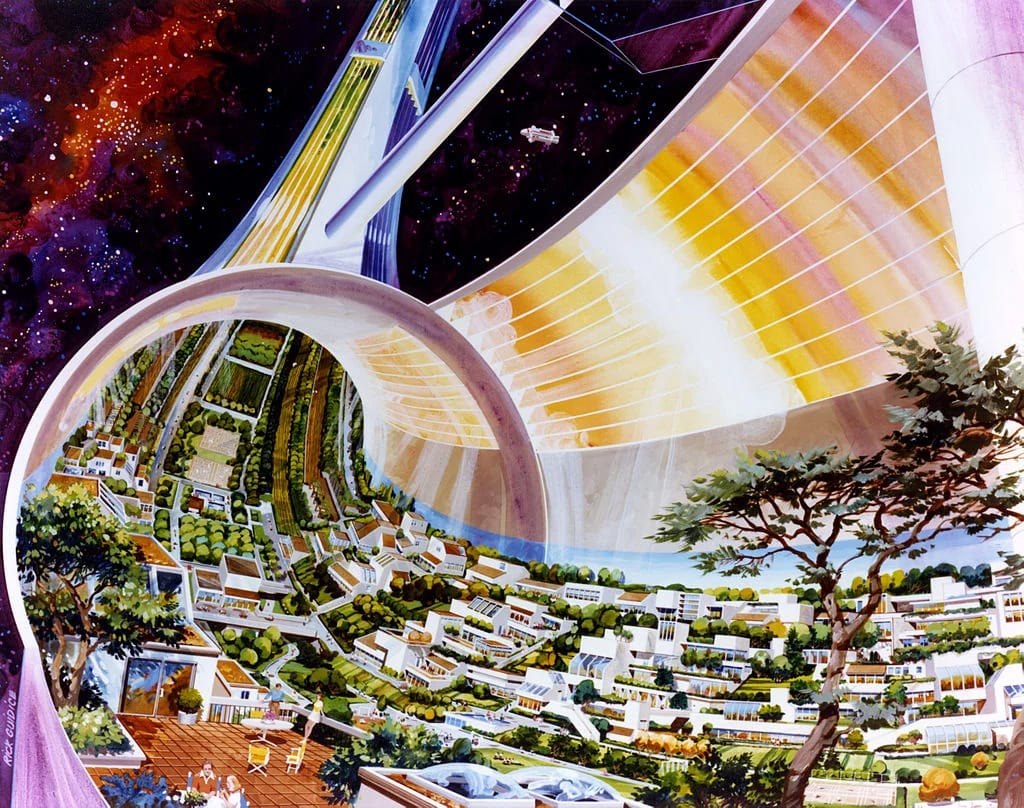

Cutaway view of a Stanford Torus Space Colony, designed by NASA, 1975.©

The global extraction of materials has been steadily increasing, driven by population growth, economic development, and industrial expansion. According to the United Nations Environment Programme (UNEP), the total global material extraction reached approximately 100 billion metric tons in 2019.

In the last five years, humanity has consumed 500 billion tonnes of materials. That is nearly equal to what was consumed during the entire 20th century.

Year on year, we are smashing through planetary boundaries—our safe environmental limits. Right now, six of the nine key planetary boundaries have been broken.

These include overloading our land use, chemical pollution into air and seas, biogeochemical flows of nitrogen and phosphorus runoff, ocean acidification, freshwater depletion, climate change, and biodiversity loss.

As we buy more things, eat more food, travel, and work more, we use more resources.

In 10 minutes (how long it may take you to read this piece), we will have:

- 456,000 pairs of shoes manufactured

- 1,620 cars rolling off the production line

- 53,000 mobile phones made

- 10 million bottles of water filled

This equates to 70% of global greenhouse gas (GHG) emissions (currently at 37.4bn tonnes). All the extraction, processing, manufacturing, and usage emits a lot of carbon. And it’s not just GHGs—materials are driving over 90% of total global biodiversity loss and water stress.

Our world is built on a very linear economic flow, and these are big flows that move around the world. Design is part of the well-oiled, highly subsidized system that externalizes the extraction and exploitation of natural resources, using the planet as a bottomless source of free raw material. Moreover, resource extraction is forecast to double between now and 2050.

When we consider that global future growth will be in the green sector, and that this growth cannot put further stress on the planet, circular design is fundamental.

Innovation in Materials: Why Speed is Crucial

Material innovation can take decades to accelerate into an off-the-shelf reality. It took more than 20 years to establish the commercial use of carbon fiber in aeroplanes and a further 30 years before it became the primary material for the Boeing 787. But the future isn’t what it used to be. We are at a moment in time where good ideas, coupled with accelerated action, are urgently required.

Deep tech like AI may come to our rescue, helping to take the risk out of material development and fast-tracking new recipes that can drop into our existing manufacturing processes. Robots are already helping us to accelerate prototyping and construction in ways we would not have imagined in past decades.

I appreciate that “innovation” is a much-overused word, but when talking about future trends in construction materials, it is highly relevant. If we look beyond the current discussions surrounding engineering efficiency, manufacturing, and energy improvement, we catch glimpses of material innovations that, in ten or maybe twenty years’ time, will accelerate the birth of a new era in the built environment.

Right now, these materials and technologies are still in the minds of budding green chemists (the unicorns of the biotech sector). Some are first prototypes growing in biotech start-up test tubes, and others are concepts yet to be fully proven in a science paper.

Examples of Material Innovation

Fabula:

If food waste were a country, it would be the 3rd largest emitter of greenhouse gases (after China and the USA). Reducing food waste is the top solution to the climate crisis, according to Project Drawdown—ranking even above energy efficiency in buildings and electrifying cars.

Using manufacturing techniques from the pressed wood board industries, Japanese tech start-up Fabula has been freeze-drying and pulverizing food scraps into powder, which they press into boards under high pressure. Using the biological makeup of the food waste means no adhesives are required to bind the material (unlike many bio-material composites). Chinese cabbage waste creates a board with bending strength four times stronger than concrete.

Seprify:

Who knew white was so impactful? The purest of colors has its origins in the mined titanium mineral. Ninety-three percent of all mined titanium dioxide is used to make things white, monopolizing the market from paint to plastic, toothpaste to skimmed milk. The process of extracting this mineral is damaging to the environment and biodiversity.

Inspired by the Cyphochilus beetle, whose chaotic but perfectly placed scales refract all light wavelengths, tech start-up Impossible Materials has created cellulose-based white pigment technology without additional minerals.

Cypris Materials:

Paint and coatings chemistry comes with significant upstream and downstream environmental and health impacts, including toxic additives, heavy metals, polluting processes, health hazards, and untraceable production. At the end of their life cycle, unused paint is treated as hazardous waste, requiring special disposal. Of the 320 million litres of paint sold in the UK each year, 50 million litres go to waste.

Biomimicry research into the iridescent blue of the Morpho butterfly’s wings revealed how light-interacting nano structures on its scales reflect and deflect the colour spectrum, creating beautiful iridescent hues even though the wings are translucent. Cypris Materials has developed a structural colour nanotechnology that creates a colour palette free of pigments and dyes.

So much is happening, but it requires investment, growth, AI, and supply network knowledge.

Where do we do the investigation? Who supports it?

Materials are central to the story of human prosperity, but we must find ways to cut the tremendous costs we are now paying. It’s a very skewed system, weighted toward the economics of global scale, subsidies, and very few financial consequences for the environmental impacts of extraction, all the way through to the end of use life—hidden from view, away from the end product.

Sophie Thomas is a long-time vocal leader in design and circular economy design principles. She works closely with businesses to radically reconsider material use through design, research, and innovation, and in 2022 co-founded the climate-tech venture studio, etsaW, building innovation in the transformation of waste streams into new materials and growing new businesses that work in the circular economy.